Ultrasonic Plastic Welding Machine

Ultrasonic Plastic Welding Machine

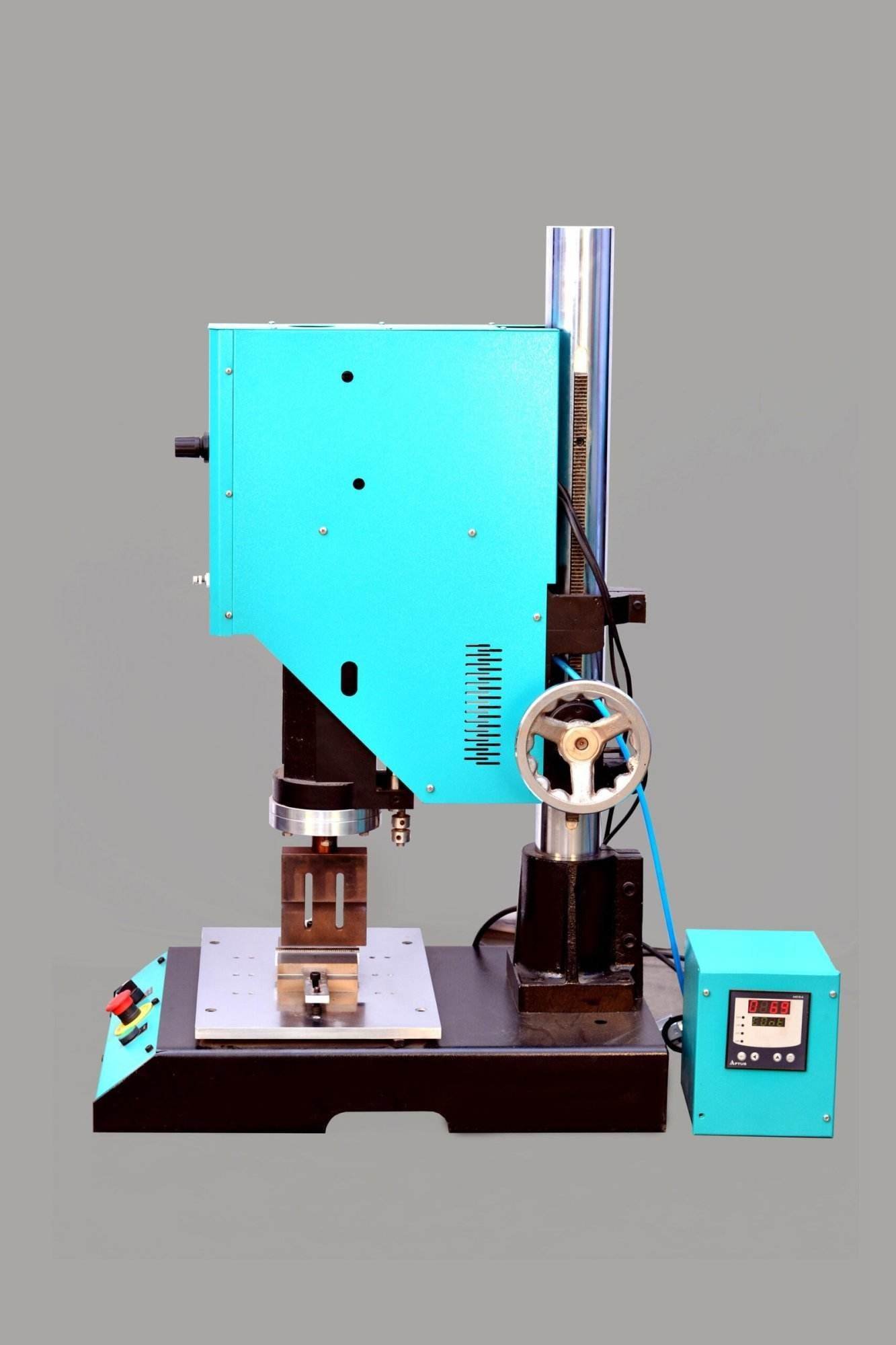

ULTRASONIC PLASTIC WELDING MACHINE – MODEL NO: MT01

Marck Techno delivers a high-quality Ultrasonic Plastic Welding Machine engineered for accurate, efficient, and contamination-free plastic joining. This advanced plastic welding solution utilises high-frequency ultrasonic vibrations to create controlled heat at the joint, enabling thermoplastic components to bond smoothly without using adhesives, screws, or mechanical fasteners. Designed for flexibility and dependable performance, the ultrasonic plastic welder is widely used across automotive, medical, electronics, packaging, and consumer product industries, producing strong and uniform welds while protecting sensitive plastic parts.

The machine features user-friendly controls, customizable settings, and a robust construction, making it suitable for diverse applications and various plastic materials. It helps shorten production cycles, enhance weld quality, and lower energy usage, ultimately improving manufacturing productivity. Backed by Marck Techno’s focus on innovation and precision, this ultrasonic plastic welding machine offers a reliable, fast, and cost-efficient solution for eco-friendly plastic bonding. From intricate components to larger assemblies, it ensures consistent results and superior performance.

Our Ultrasonic Plastic Welding Machines

Designed with precision engineering and advanced technology, our ultrasonic welding machines deliver unmatched performance and reliability. Here are the reasons why our machines stand out:

- Precision Control: Achieve uniform welds with our machines’ precise control over welding parameters, including amplitude, pressure, and duration.

- Versatility: From intricate micro-welding to large-scale production, our machines cater to diverse welding needs across various industries.

- Efficiency: Streamline your production process with fast cycle times and minimal setup requirements, maximizing productivity and reducing downtime.

- Quality Assurance: Ensure consistent weld quality with built-in monitoring systems and real-time feedback mechanisms, minimizing defects and enhancing product reliability.

- User-Friendly Interface: Intuitive controls and user-friendly interfaces make operating our machines a breeze, reducing training time and optimizing workflow.

- Durability: Engineered for durability and longevity, our machines are built to withstand the rigours of continuous industrial use, ensuring long-term performance and reliability.

| MODEL NO | MT 01 (20/1500) | MT 01 (18/1500) | MT 01 (20/2000) | MT 01 (15/2600) | MT 01 (15/3200) |

| OUTPUT FREQUENCY | 20KHZ 1500W | 18KHZ 1500W | 20KHZ 2000W | 15KHZ 2600W | 15KHZ 3200W |

| INPUT POWER | 220V,1P | 220V,1P | 220V,1P | 220V,1P | 220V,1P |

| WEIGHT | 90 KG | 90 KG | 90 KG | 100 KG | 100 KG |

| DIMENTIONS(MM) | 460*700*1000 | 460*700*1000 | 460*700*1000 | 460*700*1000 | 460*700*1000 |

| WELDING AREA | UPTO 90MM DIAMETER | UPTO 100MM DIAMETER | UPTO 105MM DIAMETER | UPTO 120MM DIAMETER | UPTO 150MM DIAMETER |